Engineering Service

Pipeline product performance testing technical services

1. Common pipeline noise problems

In our daily life, there are common noise problems in piping systems in industrial fields such as air-conditioning piping, automobile intake/exhaust systems, and aviation. The noise and corresponding noise reduction measures are: · Noise generated by the power unit itself

: ·

Pipeline Silencers are used to suppress;

· Aerodynamic noise caused by valves inside the pipeline:

·Optimization of aerodynamic characteristics of valves and flow limiting rings

· Noise caused by pipeline vibration:

·Increase the pipeline wall thickness or improve the pipeline stiffness to reduce noise.

Building air conditioning piping system/engine intake and exhaust system

Aviation piping system

Adding such noise reduction measures will cause changes in the aerodynamic and acoustic characteristics of the pipeline system. How to effectively test them has become one of the main considerations in the pipeline design process.

2. Introduction to BOACH acoustic pipeline acoustic testing solutions

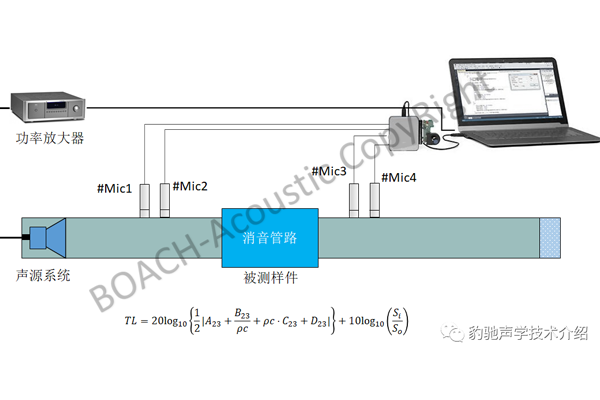

· Introduction to silencer transmission loss testing

· During the design process, pipeline silencers need to conduct transmission loss performance testing to verify the difference between the design performance of the silencer and the actual performance.

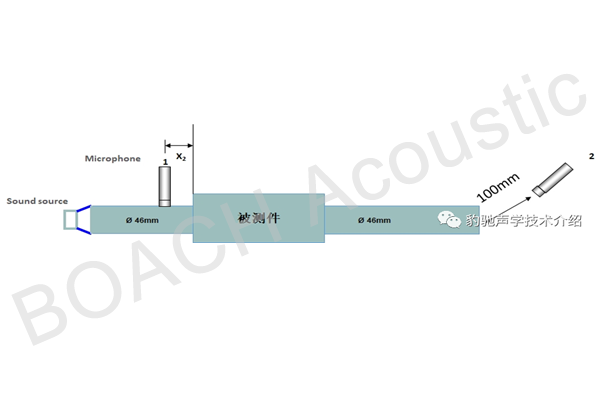

Transfer loss test principle

Transmission loss test bench

· Currently, BOACH Acoustics provides customers with the following testing services:

· 1) Product TL performance testing;

· 2) Mass production product TL consistency testing;

· 3) Product resonant cavity noise cancellation frequency testing, etc.

· When there is air flow inside the product during operation, BOACH Acoustics also customizes a transmission loss test bench for customers with the presence of air flow . It can be customized based on the dual load or dual sound source method. At the same time, BOACH Acoustics also provides external testing services. .

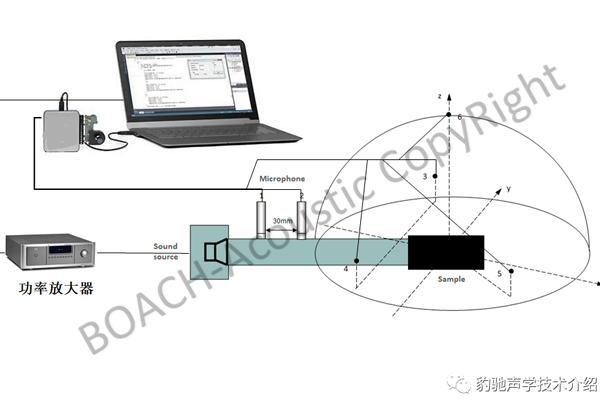

· Introduction to pipeline radiation noise testing

· When boosting equipment (air compressor, turbocharger, compressor, etc.) is working; due to the pressure pulsation inside the pipeline, the pressure and sound waves in the pipeline are excited, causing pipeline vibration. Sound;

· How to effectively evaluate the radiated noise capability of pipelines is generally evaluated through the method of pipeline radiated noise testing.

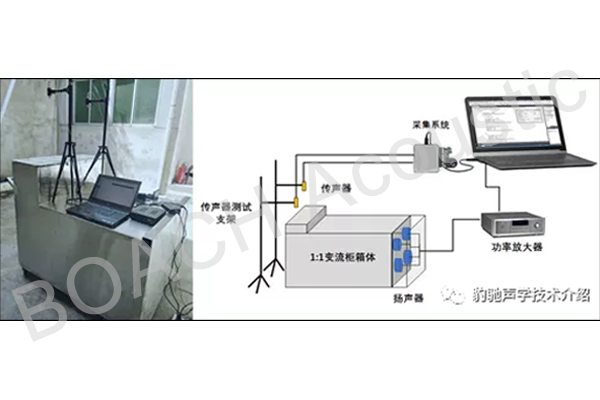

Principle of pipeline radiated noise testing

Pipeline radiated noise test bench

· Remarks:

· Testing generally requires testing in conjunction with an anechoic chamber. If the test is conducted with an anechoic chamber, the accuracy can be guaranteed;

· BOACH Acoustics currently conducts different types of performance tests for customers on plastic pipes, glass fiber pipes, etc. Work.

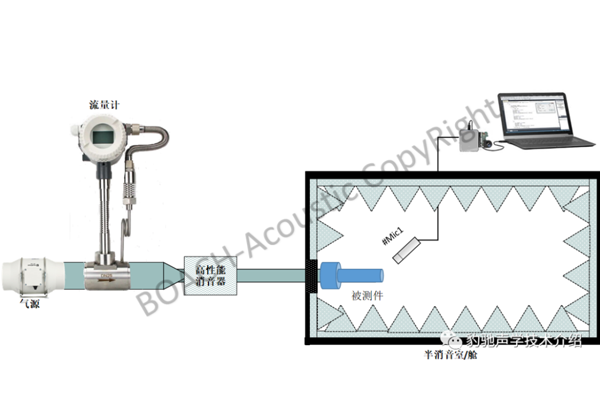

· Introduction to pipeline aerodynamic noise testing

· Pipeline aerodynamic noise: Due to changes in the internal configuration of the pipeline, airflow distortion is caused, resulting in aerodynamic noise caused by overall or local pulsation of the pipeline; · To address

this type of noise problem, BOACH Acoustics combines independent The developed aerodynamic noise test bench currently provides customers with pipeline aerodynamic noise testing services.

Principle of pipeline radiated noise testing

·Remarks:

· Based on the above test bench, early abnormal sound or aerodynamic noise testing can be carried out on structures such as flow restriction rings, valves, elbows, etc. that affect the stability of air flow in the pipeline, thereby guiding product design and development.

· Introduction to pipeline sound attenuation and insertion loss testing

· Pipeline sound attenuation: To evaluate the difference in pipeline radiation noise before and after installation of the pipeline system, the radiation noise at the pipe mouth is generally used as the assessment point; ·

For this type of noise problem, BOACH Acoustics combined with the independently developed aerodynamic noise test bench currently provides customers with pipeline aerodynamic noise testing services.

· Generally, it is necessary to simulate various boundaries such as sound source and simulated impedance, which is difficult to completely match the actual vehicle state. For this reason, laboratories generally use the no-flow state to conduct simulation tests. This test is directly related to the sound source characteristics;

· Based on this type of testing, BOACH Acoustics currently provides customers with this type of testing services based on actual conditions.

Sound attenuation test principle

Sound attenuation test of a car air intake system

Insertion loss test of a high-speed railway auxiliary converter cabinet

Contact us

Phone:

Email:

Address:

Room 901, Building 1, Phase 2, Yungu Phase 2, Fengxi New Town, Xixian New District, Xixian New District, Xi'an City, Shaanxi Province

Room 307, Building 1, Harbin Institute of Technology Robot Industrial Park, No. 488 Qianjin East Road, Economic Development Zone, Kunshan City, Jiangsu Province

Site-wide search

Please enter your keywords to learn about our company