Systemic solutions

-

Automobile Industry

-

Low Noise Solution For Intake And Exhaust Systems

-

Interior Product Performance Optimization And Cost Reduction Solutions

-

Low Noise Solution For Hydrogen Fuel Cell System

-

Low Noise Solution For Vehicle Electric Drive System

-

Low Noise Solution For Vehicle Air Conditioning System

-

Vehicle Damping Layout Optimization And Lightweight Solutions

-

-

Aviation Industry

-

Material Industry

-

Other Industry

Interior product performance optimization and cost reduction solutions

1. EV/CV Engineering Challenge EV/CV

1.1 Challenges faced in EV/CV vehicle development

1.2 Introduction to conventional vehicle interior design and development methods

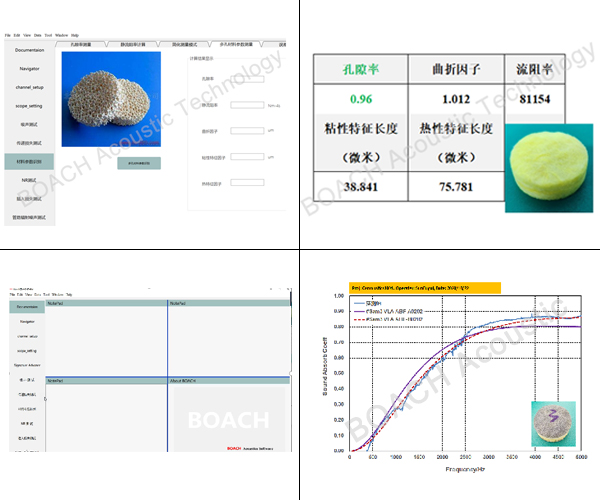

· Using counterweights for interior products and parts, and designing and developing vehicle and parts based on statistical energy methods, existing problems:·Inability to

effectively evaluate the impact of interior parts themselves on vehicle NVH The impact of mid- and low-frequency performance;

· The SEA method has problems with mid- and low-frequency analysis accuracy.

· Introduction to the differences between conventional interior layout optimization methods and the method introduced by BOACH.

|

Comparative item |

Traditional body interior and parts modeling methods |

New technology for material identification and modeling based on BOACH |

|

Sound-absorbing material property description |

Only consider the impact of quality on the entire vehicle |

Sound-absorbing materials are characterized using microscopic parameters |

|

Material location description |

The dissipative characteristics of the material are reflected in the global parameters of the model, Non-precise positioning; the model parameters used by the part are in SEA Reflects higher frequency |

The dissipative properties of the material are precisely located in the distributed area And the FEA model can accurately capture the mid- and low-frequency effects |

|

Material thickness (process) description |

Material thickness has no effect on material parameters |

By simulating the impact of different thicknesses and process compression on materials , Obtain materials in different process states Parameters, combined with the physical volume of the finite element simulation material, including shape and thickness |

|

Simulation tools |

Nastran or Altair Opstruct+SEA |

Acoustic finite element + SEA |

|

Applicability to optimization processes |

A certain degree of optimization can be done, but local optimization cannot be done. Work to achieve weight reduction or NVH performance improvement |

Using acoustic finite elements with API programming and optimization algorithms, Can design optimization work regarding position and thickness, materials, etc. |

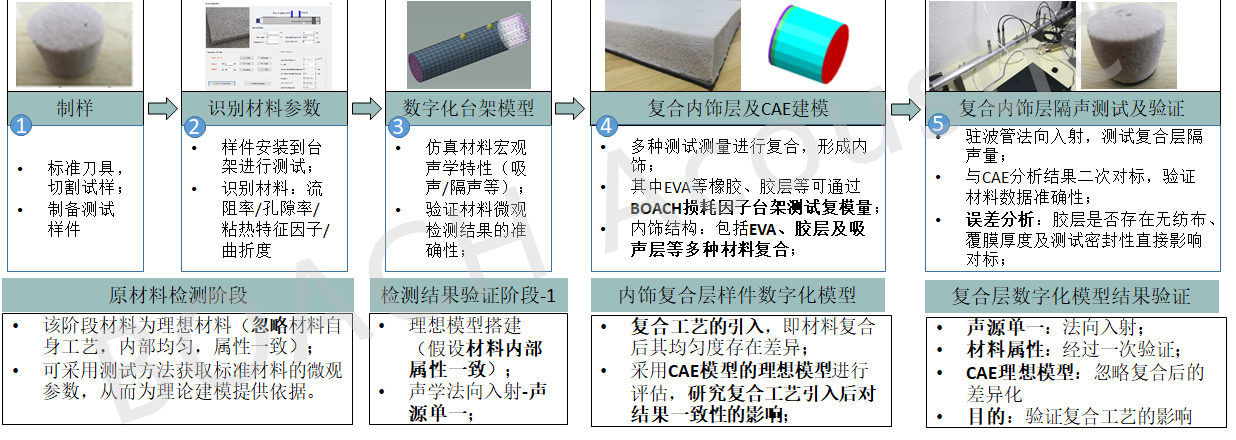

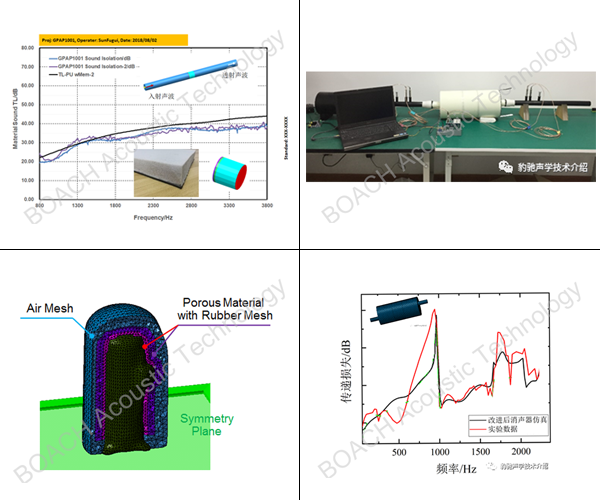

02. BOACH acoustic interior layout optimization and cost reduction forward design and development solutions:

· Identify material types : 1) PU foam; 2) PET fiber cotton; 3) Bi-component fiber cotton; 4) Fabric, etc.

· Layout optimization goals :

· Based on the perspective of NVH performance evaluation, conduct lightweight and cost reduction design analysis of the entire vehicle;

· Develop automated command flow based on acoustic finite element + statistical energy to achieve automatic optimization of material layout, and pass the test method for performance verification.

03. BOACH acoustic interior product performance optimization and cost reduction solution application cases:

· Conduct material performance testing based on material samples provided by a customer, and use the test results to obtain basic parameters of materials such as process/preparation; ·

Use CAE analysis methods to conduct CAE analysis and performance optimization of samples.

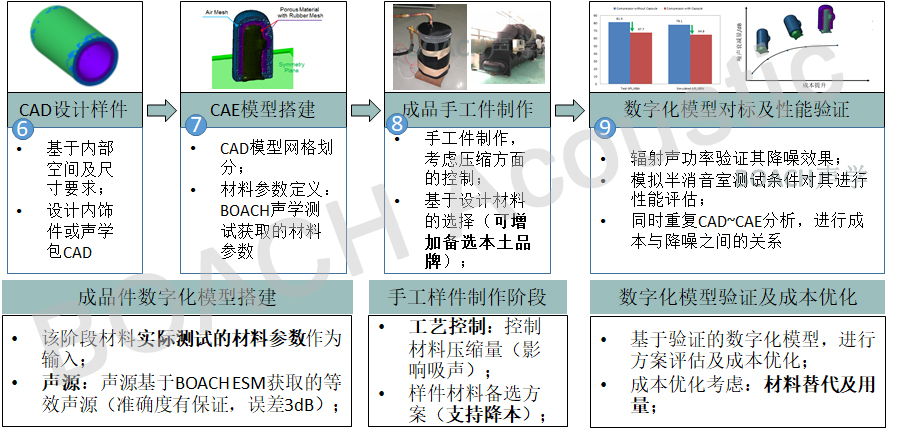

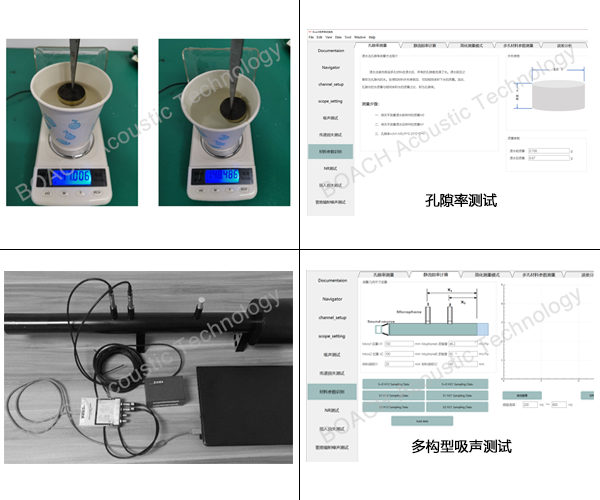

· Material sound absorption/sound insulation testing, porous material density and porosity testing;

· Support material sound absorption and sound insulation testing based on impedance tube testing standards to obtain sound absorption/sound insulation curves that change with frequency;

· Mainly test the macro parameters of materials;

· Material/sample flow resistivity, viscosity characteristic factor, thermal characteristic factor and tortuosity test;

· Foaming materials need to detect the modulus, which can be tested through the material loss factor test bench;

· Currently detectable materials: foam materials, felt, fiber cotton, metal fibers, foam ceramics, etc.

· Multilayer composite material modeling research;

· Design and development of sound-absorbing and insulating components;

· Acoustic package/muffler design, development and cost optimization;

Contact us

Phone:

Email:

Address:

Room 901, Building 1, Phase 2, Yungu Phase 2, Fengxi New Town, Xixian New District, Xixian New District, Xi'an City, Shaanxi Province

Room 307, Building 1, Harbin Institute of Technology Robot Industrial Park, No. 488 Qianjin East Road, Economic Development Zone, Kunshan City, Jiangsu Province

Site-wide search

Please enter your keywords to learn about our company